- Where Dealerships Lose Money: The Service Bay Problem

- Why Service Economics Differ from Sales

- Where Variance Destroys Margin

- Predictive Maintenance: Limited by Data Infrastructure

- Information Friction Limits Technician Output

- Parts Inventory: Cash Trap and Throughput Bottleneck

- Scheduling: The Highest Leverage Improvement

- What Operationally Disciplined Service Looks Like

- Implementation: Process Before Technology

- The Fixed Operations Opportunity

- Sources

Where Dealerships Lose Money: The Service Bay Problem

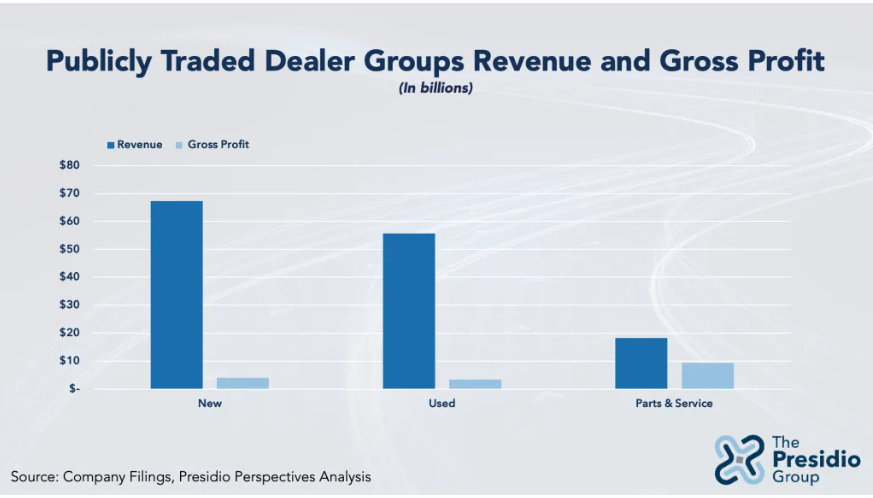

Fixed operations generated over 50% of gross profit at franchised dealerships in 2024. Service margins exceeded 40%. New vehicle margins sat at 6.1%. These numbers clarify where the money is. They also clarify where most dealerships waste it.

The problem isn’t demand. Service bays see consistent traffic. The issue is execution. Coordination failures bleed revenue daily. Empty bays at noon. Technicians waiting for parts. Vehicles returning for the same issue. Each failure looks minor. Collectively they determine whether a dealership makes money or merely breaks even.

AI improves this when it reduces waste, smooths variability, and supports decisions at scale. The objective stays narrow: increase throughput per bay, increase technician utilization, reduce working capital in parts, reduce repeat visits.

Why Service Economics Differ from Sales

Vehicle sales fluctuate with incentives and inventory. Service creates recurring revenue across the vehicle lifespan. Industry data from Q2 2025 shows fixed operations gross profit grew 8.4% year-over-year while new vehicle margins compressed. This pattern repeats. Service stabilizes. Sales swing.

Service departments operate under hard constraints. Fixed bay count. Fixed technician headcount. Fixed hours per day. Unused capacity disappears. An empty bay at 2 p.m. generates zero revenue. A repeat repair consumes time that could have served a paying customer. A stockout blocks both labor revenue and parts margin.

Profitability depends on utilization rate and cycle time. Moving utilization by three percentage points can generate six-figure annual impact without capital investment. This is an operations problem. Technology helps only when it eliminates friction.

Where Variance Destroys Margin

Service operations fail quietly. Morning appointment clusters create queues and technician idle time by afternoon. Diagnostic time runs long without pattern data. Parts arrive late or not at all. Customers no-show at 15% rates. Each event appears tolerable. Compounded across 250 working days they create permanent margin drag.

Airlines forecast load factors. Hospitals manage OR schedules. Dealerships traditionally relied on buffers: excess parts inventory, optimistic time estimates, overbooking. Buffers consume capital and generate their own failures.

Forecasting tools reduce variance at the source. Statistical models consistently outperform human intuition at predicting no-show probability, job duration, and parts requirements. They replace guesses with distributions. Small improvements in prediction accuracy compound rapidly.

Predictive Maintenance: Limited by Data Infrastructure

Predictive maintenance sounds transformative. Detect impending failures, schedule proactive service, eliminate breakdowns. Execution requires complete service history, standardized repair codes, consistent telemetry, and unified data platforms.

Most dealerships operate fragmented systems. Service notes vary by technician. Repair codes lack standardization across brands. Vehicle data sits in manufacturer silos. Customer records fragment across DMS, CRM, and scheduling platforms.

Complex machine learning models trained on inconsistent data produce unreliable predictions. Simpler methods deliver better ROI: historical service intervals, mileage-based triggers, failure probability by component age. These approaches work with available data and avoid the overhead of maintaining ML infrastructure.

Better data discipline produces better outcomes. Standardize job codes first. Enforce documentation protocols second. Complex modeling third.

Information Friction Limits Technician Output

Technicians spend 30-40% of productive hours on information tasks. Looking up repair procedures. Searching part numbers. Writing service notes. Entering warranty claims. Switching between five different systems to complete one repair order.

Mechanical skill rarely limits throughput. Information flow does.

Decision support tools reduce this tax: auto-populated job cards based on symptoms and VIN, voice-to-text for service notes, automated parts cross-reference, pre-filled warranty documentation, single-screen workflows.

A 10% reduction in average job cycle time across a 15-bay shop produces approximately 1,800 additional billable hours annually. At $150/hour that compounds to $270,000. Most of this comes from eliminating administrative friction, not increasing mechanical speed.

Human expertise remains central. Systems simply waste less of it.

Parts Inventory: Cash Trap and Throughput Bottleneck

Parts rooms appear organized. Financially they hide two problems: capital inefficiency and throughput constraint.

Capital inefficiency shows up as slow-moving inventory. Parts sitting 12+ months with zero demand tie up working capital at zero return. Emergency orders for common items incur premium freight costs. The average dealership carries $400,000-$600,000 in parts inventory. Poor forecasting inflates this by 20-30% while simultaneously creating stockouts on fast-moving SKUs.

Throughput constraint appears when repairs stall awaiting parts. A $1,200 brake job delayed three days costs the labor revenue, delays subsequent appointments, and risks the customer defecting to an independent shop.

Demand forecasting addresses both. Time series models with seasonality adjustments predict requirements by part number. Reorder point optimization balances carrying cost against stockout risk. These calculations update continuously as new service orders arrive.

Dealerships using algorithmic inventory management typically see working capital reduction of 15-25% while improving fill rates. The math is straightforward. The execution requires consistent data and disciplined process.

Scheduling: The Highest Leverage Improvement

Appointment scheduling creates asymmetric impact. Small improvements in schedule density and accuracy cascade into large profit changes. Most service departments still use static appointment blocks and manual adjustments.

Historical data reveals predictable patterns that go unused. Job duration varies by repair type and technician. Customer no-show probability varies by appointment channel and lead time. Workload imbalances between technicians create idle capacity.

Predictive scheduling addresses this systematically. It estimates job duration using repair type, vehicle data, and technician history. It adjusts appointment density based on predicted no-show rates. It balances work across the team. It automatically refills cancelled slots.

A well-implemented scheduling system moves effective utilization from 65% to 75-80%. In a constrained capacity business this produces 15-23% revenue increase without adding bays or headcount. Return on investment typically pays back in under six months.

What Operationally Disciplined Service Looks Like

The resulting department doesn’t look futuristic. It looks predictable.

Customers receive service reminders based on mileage intervals and repair history, not arbitrary time periods. Booking happens digitally with real-time availability. The system predicts required parts from symptom data and VINs, ordering before the appointment. Technicians start jobs with pre-staged parts and pre-loaded diagnostic protocols. Fewer vehicles return for the same issue within 30 days. Daily workload stays steady rather than spiking unpredictably.

Physical constraints don’t change. Bay count, technician count, and tool availability still define capacity. Intelligence simply coordinates those constraints with fewer surprises and less waste.

Margins improve when variance decreases. This is what AI enables in service operations.

Implementation: Process Before Technology

Technology implementations fail when they skip foundational work. Start with operational discipline:

- First, clean and standardize service data. Fix inconsistent job codes. Enforce documentation standards. Establish data quality metrics.

- Second, measure baseline performance. Track utilization rate by bay and technician. Measure average cycle time by job type. Calculate parts fill rate and inventory turns. Quantify no-show rates and repeat repair frequency.

- Third, implement basic forecasting. Start with appointment no-show prediction. Add job duration estimation. Deploy parts reorder optimization. Each component solves one coordination failure.

- Fourth, automate administrative overhead. Voice-to-text notes. Auto-populated forms. Integrated warranty processing. Eliminate system switching.

- Fifth, introduce advanced modeling only after the foundation holds. Predictive models require clean data and consistent processes. Without those prerequisites they generate noise instead of signal.

Industry research on aftersales optimization consistently points to the same pattern. Systematic process redesign outperforms isolated technology purchases. Progress accumulates through incremental improvements. Each change looks modest. Compounded they shift department economics.

The Fixed Operations Opportunity

Fixed operations accounts for only 12.6% of total dealership revenue but generates disproportionate gross profit. Q2 2025 data shows fixed operations gross profit grew 8.4% year-over-year while new vehicle margins compressed. This divergence clarifies where operational improvements matter most.

Service and parts already drive profitability. The opportunity lies in extracting more value from existing capacity. Most service departments operate at 65-70% effective utilization. Physical constraints don’t prevent improvement. Coordination failures do.

AI tools address coordination problems by reducing information friction, smoothing demand variance, and supporting repetitive decisions at scale. The technology serves operational discipline. It doesn’t replace it.

In constrained capacity systems, small efficiency gains produce disproportionate margin improvement. A three percentage point increase in utilization or a 10% reduction in cycle time changes annual performance without expansion capital. These gains come from better coordination, not heroic effort.

The market has noticed. The automotive AI market is projected to reach $7.75 billion by 2030, with near-universal adoption expected in service departments. Dealerships investing now in operational fundamentals and appropriate technology will capture advantage before those improvements become table stakes.

The economics are clear. Execution requires discipline, but the impact on margins compounds daily.

Sources

- Ernst and Young. “Aftersales Strategies for Growth in the Automotive Industry.”

- McKinsey and Company. “Optimizing Dealer Profitability with a Service Center Tune Up.”

- National Automobile Dealers Association. “NADA Data: Industry Financial Profiles and Reports.”

- Reuters. “LKQ Beats Quarterly Profit Estimates on Strong Auto Parts Demand.”

- The Presidio Group. “Margin-rich fixed operations gives dealerships an avenue to offset profit decline elsewhere.”

- Haig Partners. “2025 Dealership Buy-Sell Insights: Profitability, Valuations, and Market Opportunities.”

- Charisma! Insights. “Service department AI now a ‘strategic imperative’ for dealerships, report says.” Auto Remarketing.

Stay Updated

Enjoyed this article?

Get more insights on AI, product strategy, and digital growth delivered to your inbox.

No spam. Unsubscribe anytime.

Keep Reading